Aluminium die casting inzira umo yakanyungudutswa aruminiyamu alloy inomanikidzwa kuita simbi inofa kana mold pasi pekumanikidzwa.Inowanzo shandiswa pakugadzirwa kwehuwandu uye inogona kugadzira zvikamu zvine ruzivo rwakanyanya pamwe nezvikamu zvine kushivirira kwakasimba pamutengo wakaderera.Zvikamu zvinogadzirwa kubva kualuminium die casting zvine zvakanakisa zvemuchina uye zvinoshingirira mukuora, kupisa, uye kupfeka.

• Aluminium die casting inopa mabhenefiti akati wandei, mamwe acho anosanganisira:

• Zvikamu zvisinganzwisisiki uye zvakasimba zvinodhura zvakanyanya kudarika mamwe marudzi esimbi

• Kuvandudza kushanda zvakanaka nekuda kwekupfupika kwekutungamira uye kuderedzwa kwemarara

• Kuwedzera rusununguko rwekugadzira nekuda kwekusagadzikana kwayo, zvichibvumira maumbirwo akaoma kuti aumbe nekukurumidza uye nyore

• Kuramba kwakakura kune ngura, kupisa, uye kupera zvichienzaniswa nedzimwe simbi

• Kugona kwekugadzirwa kwehuwandu, neine aruminiyamu alloys yakawanda inokwanisa kutsungirira kudzvinyirira kwakanyanya uye tembiricha

Aluminium die casting inzira inoshamisa yekugadzira yakasiyana-siyana inoshandiswa kugadzira huwandu hwakasiyana hwezvikamu zvemaindasitiri akasiyana.Kubva kumidziyo yemotokari kuenda kumishonga yekurapa uye nezvimwe, aluminium die casting inogona kushandiswa kugadzira chero chinhu, senge:

• Indasitiri yemotokari:Zvikamu zvakasiyana zvinosanganisira zvemukati trim, transmission casings, mabhuroko einjini uye anokwirisa, maraya, uye machaji masisitimu.

• Indasitiri yemuchadenga:Zvakaoma zvinhu zvakaita sepombi, masensa, actuators, shongwe dzeredhiyo uye antennae.

• Indasitiri yezvokurapa:Zvikamu zvine hunyanzvi zvakaita semavharuvhu emoyo anoisirwa, zviridzwa zvekuvhiya, orthotics uye prosthetics.

• Midziyo yemumba:Hinges nemalachi emafiriji nemichina yekuwachisa pamwe nezvimwe zvidiki zvinoda basa rakaomarara.

• nezvimwewo,.

Kusarudza iyo chaiyo aruminiyamu alloy kune yako kufa yekukanda purojekiti kwakakosha kuti uve nechokwadi chekuti chigadzirwa chako chapedzwa chinosangana nezvose zvaunoda.Heano mamwe matipi ekusarudza alloy chaiyo:

• Funga nezvesimba uye kusimba zvinodiwa zvechikamu chako.Akasiyana alloys anopa akasiyana mazinga esimba uye kupfeka kuramba, saka zvakakosha kuti usarudze alloy inosangana nezvinodiwa zvekushandisa kwako.

• Ongorora inodiwa corrosion resistance level.Aluminium alloys anogona kurapwa uye anodized kuti ape imwe dziviriro kubva mukuora, saka ita shuwa yekufunga kuti ndeipi nharaunda iyo nhengo dzako dzichada kutsungirira.

• Funga nezvemitengo yekugadzira uye nguva dzekutumira.Zvichienderana nekuoma kwechikamu, maalloys akasiyana anogona kuda nzira dzakasiyana dzekugadzira kana maturusi ekudyara, saka zvakakosha kuyera zvinhu izvi kana uchisarudza alloy yepurojekiti yako.

Tooling uye machining zvinodiwa zvealuminium kufa kukandira zvinosiyana zvichienderana nealloy inoshandiswa, kuoma kwechikamu, uye zvimwe zvinhu.Kazhinji, zvakakosha kufunga zvinotevera pakusarudza rudzi rwechishandiso:

• Kusarudzwa kwezvinhu zvekushandisa kunofanirwa kubva pane alloy iri kushandiswa uye tembiricha inodiwa kuitira kuburitsa mhedzisiro yemhando.Isu tinowanzo shandisa H13, SKD61, 8407, 8418, 8433 uye W360 yekufa cast tooling.

• Kuchenjerera kunofanira kutorwa kuti pave nekona yekunyora yakakwana kuitira kuti zvikamu zvikwanise kusuduruka kubva padhifi kana yaburitswa.Kuongorora kwakazara kweDFM kunofanirwa kuitwa pamberi pekugadzira mold.

• Chechipiri machining inogona kudiwa mushure mekukanda kuitira kuti uwane mamwe maumbirwo kana ruzivo, zvinosanganisira CNC machining, drilling, tapping uye zvichingodaro.

• Sarudzo dzePamusoro Pekupedzisa dzakadai sejecha-blasting kana vibratory polishing, anodizing, plateing kana kupenda zvinogonawo kudiwa zvichienderana nezvaunoda.

CNC Machining for Die Yakakandwa Zvikamu

Kugadzirisa matambudziko akajairika mualuminium kufa castings kunogona kutora nguva uye kudhura maitiro, asi zvakakosha kuti uve nechokwadi chemhando yezvikamu zvako.Heano mamwe matipi ekugadzirisa matambudziko akajairika nealuminium kufa castings:

• Porosity:Ongorora chikamu chako kune chero pinholes kana dzimwe nzvimbo dzinogona kutungamira kune porosity.Kana iwe ukawana chero, ita shuwa yekudzokorora tembiricha yekuumbwa, kudzvanywa kwejekiseni uye zvimwe zvinhu zvingave zvakakanganisa kuzadza kwechidimbu.

• Kukanganisa:Kana iwe ukawana kukanganisa muzvikamu mushure mekunge zvabviswa kubva mufa, tarisa kuti uone kana mold dhizaini kana nguva yekutonhora ingave iri kukonzera nyaya iyi.Ungangoda kugadzirisa aya marongero emangwana ekugadzira anomhanya kuitira kuderedza chero kukanganisa.

• Kukanganiswa kwepamusoro:Kana ukasangana nechero hurema hwepamusoro senge splay mamaki kana zvimbi, tarisa kana paine kusawirirana pakati pekumhanya kwejekiseni uye kunyungudika kuyerera, sezvo izvi zvichigona kukonzera nyaya idzi.Zvinogona zvakare kuve zvakafanira kugadzirisa ma paramita ekukanda senge tembiricha uye kutonhora mitengo kuitira kuderedza kusakwana kwepasi.

Kana chirongwa chitsva chatanga, kukurumidza prototyping zvikamu zvinodiwa pamhando dzebvunzo.Pane nzira dzakawanda dzekugadzira prototypes dzinosanganisira CNC machining, Vacuum casting, 3D kudhinda uye Rapid prototype tooling.

• CNC machining anogona kuita simbi uye epurasitiki zvikamu chero uwandu.

• Vacuum Casting ndeye 5-100 unit zvikamu zvepurasitiki nekushandisa silicon molds

• 3D Printing ndeyekudhinda ABS, PA kana Simbi zvikamu.Zvepurasitiki, 3D dzakadhindwa zvikamu hazvigone kumira zvakanyanya tembiricha.

• Rapid prototype tooling ivhu rakapfava rakagadzirwa nesimbi yakapfava seS50C kana Aluminium.Iyi mhinduro inogona kuburitsa zvikamu zvakawanda kupfuura Vacuum casting.Nguva yekutungamira ipfupi pane zvigadzirwa zvekugadzira uye mutengo wakaderera zvakare.

Zvishandiso zvatakashandisa: Mapurasitiki sePC, PMMA, POM, PP nezvimwe,.Metal sesimbi, aluminium, ndarira, mhangura uye zvichingodaro.

Nzira yekugadzira silicon zvikamu

Kuti ugadzire chikamu chesilicone, iwe uchada kushandisa maitiro ekuumba jekiseni.Izvi zvinosanganisira kunyungudusa purasitiki mumushini wejekiseni uye kuipinza mugomba rakavharika, umo inotonhora nekuoma kuti itore chimiro chaunoda.

Mamwe maitirwo aungashandisa anosanganisira kudhinda kuumba, vacuum casting, kana 3D kudhinda.Imwe neimwe nzira inopa yakasarudzika mabhenefiti uye yakashata zvichienderana nerudzi rwechikamu chauri kuedza kugadzira.

Nezvese nzira, kuwana tembiricha yakakodzera uye kudzvanywa kwakakosha pakuzadzisa zviyero uye zvinhu zvinodikanwa zvezvinhu.

Zvishandiso zvesilicon zvikamu

Kune akawanda maindasitiri anogona kushandisa silicon yakapfava zvikamu seMotokari, Medical, Electronic, houseware, kitchenware, uye vamwe vakawanda.Kune zvikamu, kazhinji unogona kuwana izvi seGaskets, Seals, O-rings, Air mafirita, Hoses, Lighting components, Makesi enharembozha, Keyboard zvivharo, Waya uye tambo insulation uye akawanda Midziyo yekurapa.

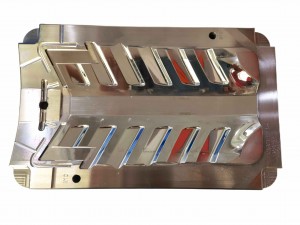

Metal stamping parts inhengo dzesimbi dzakagadzirwa kuburikidza nekuita kwesimbi stamping, nzira yekugadzira inosanganisira kubaya, kucheka, kana kugadzira simbi masheets kuita maumbirwo anodiwa.

Metal stamping inoshandiswa kugadzira zvikamu zveakasiyana siyana maindasitiri anosanganisira emotokari uye maindasitiri emuchadenga.

Inogonawo kushandiswa kugadzira tsika uye zvimiro zvakaoma.Mabhenefiti ekushandisa simbi stamping anosanganisira mutengo-kushanda, dhizaini yakaoma uye kuchinjika.

SPM yakabatsira vatengi mune zvakawanda zvesimbi zvidhinha zvinhu zvepurojekiti yavo yeturnkey, sevhisi yedu inoshanda yeinjiniya inogona kuchengetedza yakawanda yemitengo yavo nenguva.

Jigs uye zvigadziriso zvishandiso zvinoshandiswa kubatsira mukugadzirwa kwezvikamu zvakasiyana uye zvikamu.

Jig chishandiso chakasarudzika chinobatsira kutungamira, kubata, kana kumisa dhizaini panzvimbo panguva dzakasiyana dzekuita machining, sekuchera, kugaya, uye kuumba.

Fixtures zvigadziriso zvakanamirwa pamushini kana workbench uye zvinobatsira kutsvaga nekuchengetedza zvikamu pazvinenge zvichishandirwa.

Vanogona kuva tsika yakagadzirirwa kugadzirisa mabasa akasiyana-siyana kuti ave nechokwadi chekururama uye kubudirira.Zvose jigs uye zvigadziro zvinogona kugadzirwa nesimbi yakadai sesimbi kana aluminium uye zvakakosha pakugadzira zvikamu zvakarurama nekuedza kuduku.

SPM inogadzira jigs uye zvigadziriso zvedu pachedu jekiseni molding kugadzira uye zvakare inopa sevhisi yekuzvigadzira kune vatengi.

Kana iwe uchida izvi, ndapota taura chero nguva.