| Appliance uye Type | Electronic precision zvikamu zvinogadzirwa neakawanda cavity epurasitiki jekiseni mold, | |||||

| Chikamu zita | Mobile connector | |||||

| Resin | Upfu metallurgy zvinhu | |||||

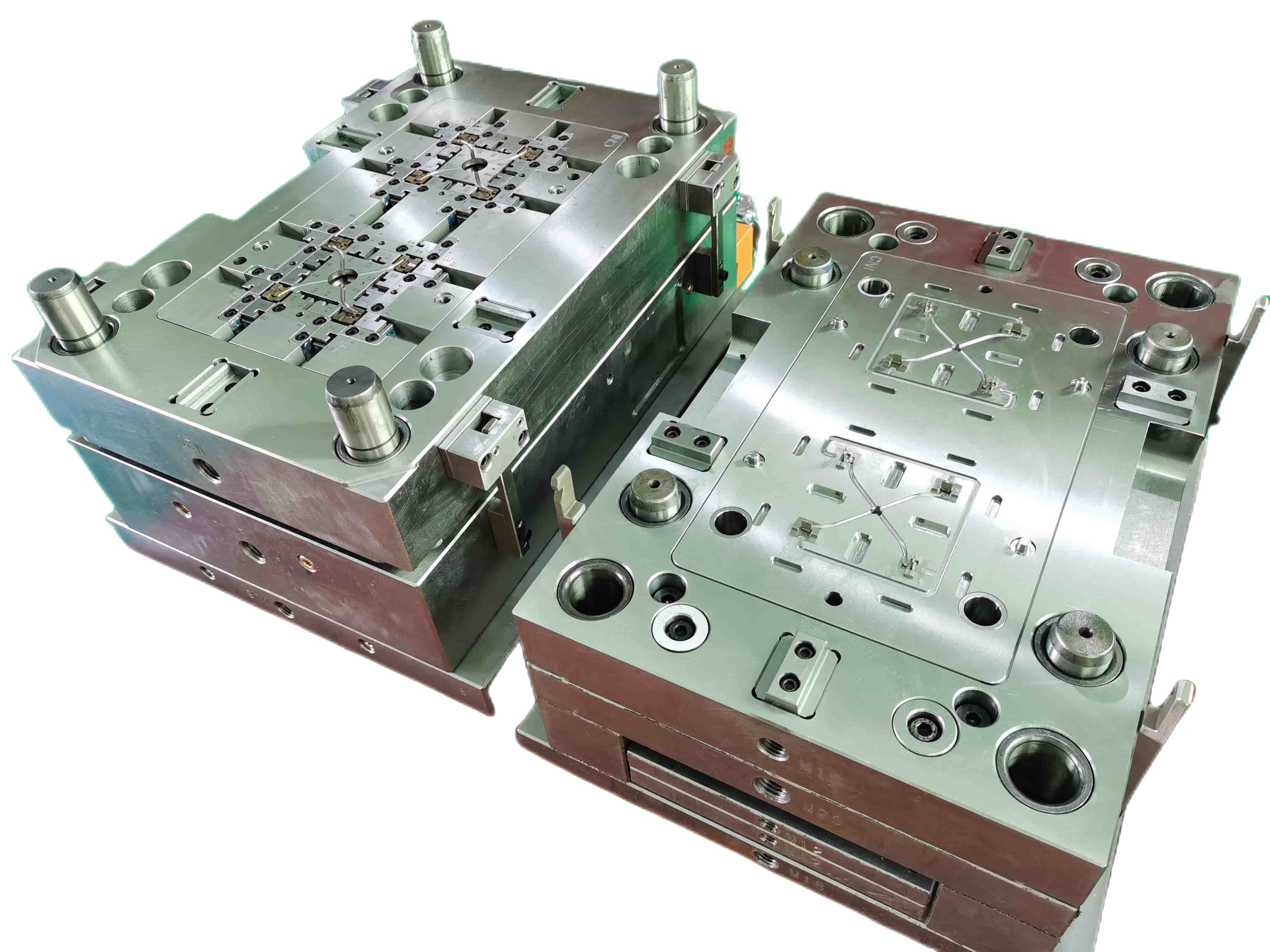

| Kwete yemhango | 1*8 | |||||

| Mold Base | S50C | |||||

| Simbi yemhango & Core | S136 HRC 52-54 | |||||

| Tool uremu | 450KG | |||||

| Tool size | 450X350X370mm | |||||

| Dzvanya Ton | 90T | |||||

| Mold life | 1000000 mapfuti | |||||

| Injection system | Anopisa mumhanyi, 2pcs Mold-master inopisa matipi | |||||

| Kutonhodza system | Kutonhora nemafuta, mold tembiricha 120 degree | |||||

| Ejection System | Matanho maviri ejection | |||||

| Special points | Powder metallurgy zvinhu, chaiyo jekiseni mold, inopisa mumhanyi, 8 cavity mold, pfupi kutenderera nguva. | |||||

| Matambudziko | Yakanyanya kushivirira kushivirira, tembiricha yekuumbwa, ipfupi mold inogadzira nguva yekutungamira uye ipfupi kwazvo yekuumba kutenderera nguva.Izvo zvinhu ndezvePowder metallurgy zvinhu zvine nguva pfupi yekutonhora uye kudiwa kwakanyanya kwemajekiseni emuchina. | |||||

| Kutungamira nguva | 4 mavhiki | |||||

| Package | Mold inogara muChina yekugadzira mapurasitiki ekuumba | |||||

| Kurongedza zvinhu | Certification yesimbi, yekupedzisira 2D & 3D chishandiso dhizaini, rinopisa mumhanyi gwaro, spare parts uye electrode… | |||||

| Shrinkage | 1.005 | |||||

| Surface finish | SPI B-1 | |||||

| Injection molding kutenderera nguva | 9 seconds | |||||

| Chechipiri kurapwa kwezvigadzirwa mushure mekuumbwa | Kupisa kurapwa kwezvigadzirwa zvakaumbwa | |||||

| Export kune | Mold inogara muChina yekugadzira mapurasitiki ekuumba | |||||

Matambudziko acho

Yakanyanya kushivirira kushivirira, tembiricha yekuumbwa, ipfupi mold inogadzira nguva yekutungamira uye ipfupi kwazvo yekuumba kutenderera nguva.

Izvo zvinhu ndezvePowder metallurgy zvinhu zvine nguva pfupi yekutonhora uye kudiwa kwakanyanya kwemajekiseni emuchina.

Chii chinonzi powder metallurgy?

Powder metallurgy inzira yekugadzira iyo inoshandisa yakamanikidzwa compaction uye sintering yesimbi zvimedu kugadzira akasiyana ezvikamu uye zvikamu.Kuita uku kunosanganisira kubatanidza simbi dzehupfu dzakaita sesimbi, aruminiyamu, bhuronzi, simbi isina tsvina uye cobalt ine mafuta ekuzora uye maajenti ekusunga asati azviisa pasi pesimba repamusoro.Musanganiswa unobva wapiswa kusvikira zvinhu zvacho zvabatana nemakemikari, zvichigadzira zvikamu zvakasimba kudarika zvechinyakare zvakakandwa kana kuti zvakagadzirwa nemichina.

Nekuda kwekusiyana-siyana kwayo, simbi yehupfu yave kuwedzera mukurumbira mukugadzirwa kwezvikamu zvakaoma zvinoshandiswa mumotokari, aerospace uye zvemagetsi zvevatengi.

Chii chinonzi high temperature mold?

High-temperature molding imhando yejekiseni yekuumba maitiro ayo anoshandisa tembiricha yakakwira uye zvinomanikidza kugadzira zvikamu zvine simba rakawanda uye kusimba.Maitirwo acho anoshanda nekudziisa mbishi thermoplastic material kusvika yanyunguduka yobva yaipinza muforoma yakavharirwa painoiswa panzvimbo pasi pekumanikidzwa.Kupisa kubva muresin yakanyungudutswa yakasanganiswa nekumanikidza kunoita kuti zvinhu zviumbe muchimiro chinodiwa chisati chatonhodza.Iyi nzira inobvumira kugadzirwa kwezvikamu zvakaoma zvinopikisa kupisa kwakanyanya uye makemikari anoparadza, zvichiita kuti zvive zvakanaka kuti zvishandiswe mumaindasitiri akadai semotokari, aerospace, zvigadzirwa zvekurapa uye zvemagetsi.

Common Plastic Material inosanganisira: PEEK, PPSU, ULTEM® (Polyetherimide, PEI), Celazole®, Vespel®, Torlon® (Polyamide-imide) nezvimwewo.

Mold dhizaini yekupisa kupisa mold

Paunenge uchigadzira molds epamusoro-tembiricha mapurasitiki zvakakosha kuti ubatanidze nzira dzekufambisa kupisa pamwe nekushandisa mapini ekupisa kuti ive nechokwadi chekuti purasitiki inotonhora zvakaenzana panguva yekuumba jekiseni.

Pamusoro pezvo, kusarudza iyo chaiyo mold zvinhu kwakakosha pakugadzira zvikamu zvinokwanisa kumira kutonhora kwakanyanya pasina kuputika kana kuputika.

Muchirongwa ichi, takashandisa simbi yeS136 ine HRC 52 ~ 54, huwandu hwekugadzira hwakakwira zvakanyanya, zvikamu 100000pcs zvaidiwa zuva rega rega, saka takashandisa 8 cavity mold uye kugadzira akawanda makopi kuti asangane nechikumbiro chehuwandu.Nekutonhodza, inotonhodzwa nemafuta uye tembiricha yekuumbwa inosvika ku120 degree.Nguva yekutenderera i9 masekonzi uye isu takashandisa 2 nhanho ejection yekuburitsa zvikamu.Ichi chikamu chichava kupisa kurapwa mushure mekuumbwa.

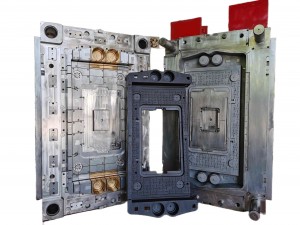

Iyo jekiseni mold chishandiso ndeye 8 cavity yakakwirira tembiricha jekiseni mold.

Plastiki ihupfu simbi yemidziyo uye zvikamu zvakaumbwa zvinoda kurapwa kwekupisa sezvo iriyo nhare yekubatanidza.

Jekiseni molding kutenderera nguva ipfupi kwazvo, 9 masekonzi pfuti imwe.

Isu takagadzira akawanda maturusi emakopi emutengi uyu.Vagadziri vedu vanoshanda zvakanyanya, yeDFM, inopera mukati mezuva rimwe, 2D marongero mukati memazuva maviri, uye 3D mukati memazuva matatu.

Nguva yekugadzira mold inotora mavhiki mana.

Kugadzira mold, kana nguva ichikurumidza, isu tinowanzo gadzira 3D kudhirowa zvakananga mushure meDFM, asi chokwadi, inofanira kunge yakavakirwa pamvumo yevatengi.

2D chimiro

3D mold design

3D mold design

FAQ

Bhizinesi redu guru nderekugadzira epurasitiki jekiseni mold kugadzira, kufa cast mold kugadzira, epurasitiki jekiseni kuumba, kufa casting (Aluminium), chaiyo machining uye nekukurumidza prototyping.Isu tinopawo kukosha-akawedzera zvigadzirwa zvinosanganisira silicon zvikamu, simbi stamping zvikamu, extrusion zvikamu uye stainle

Kwete, isu tiri chaiyo kugadzira mold uye epurasitiki jekiseni kuumba fekitori.Tinogona kupa mufananidzo wekunyoresa kuti ureve uye chero rumwe ruzivo rwaunoda kana rwuchidikanwa.Zvichakadaro, unogona kutishanyira chero nguva, kunyangwe pasina kugadzwa.

Chikwata chezuva chinopa 24/7 sevhisi yekushanda maitiro.Kwemazororo eruzhinji eChinese, kutengesa kwedu uye mainjiniya vanogona kutora basa rekuwedzera kune chero chekukurumidza kwako.Uye pazvinenge zvichidikanwa, tichaita zvakanakisisa kukumbira vashandi kuti vatore nguva yakawanda yekushanda panguva yezororo nemasikati uye mashifiti ehusiku kuzadzisa zvaunoda nekukurumidza.

Tine makore anopfuura gumi ekutumira kunze ruzivo kumusika wepasi rose, kunze kunze kwepurasitiki jekiseni mold, die cast mold, die casting parts, epurasitiki jekiseni akaumbwa zvigadzirwa uye CNC machining components etc,.

Pakugadzira mold, tine CNC, EDM, Machina ekukuya, muchina wekugaya, muchina wekuchera, nezvimwe,.Kuumbwa kwepurasitiki, tine michina yejekiseni ina kubva pa90 ton kusvika mazana mana ematani.Kuongororwa kwemhando, isu tine hexagon CMM, Projector, hardness tester, urefu geji, vernier caliper zvichingodaro.

WANA DFM YEMAHARA NHASI!

-

Plastic jekiseni kuumba purojekiti kubva Rapid p...

-

Yakakura saizi yepurasitiki jekiseni mold yemotokari ...

-

Plastic tooling mhuri mold mota muswe lig...

-

Jekiseni multi cavity mold for caps of packa...

-

Plastic jekiseni mold isa mold for Automo...

-

Yakakwira girazi faibha Nylon zvinhu mold tooling fo...