5 Injection mold mhando yakavakirwa paUS SP1-SPE chiyero

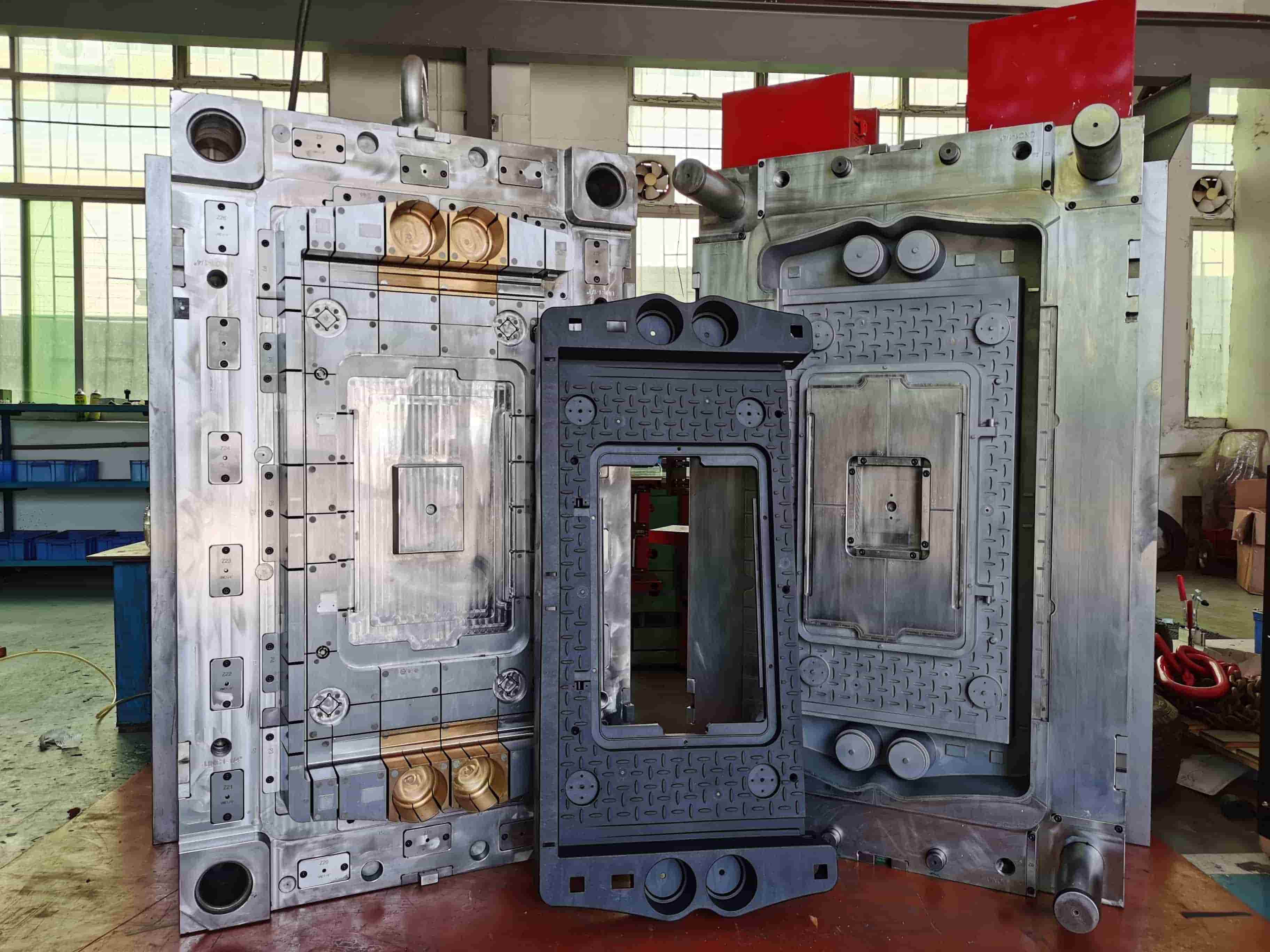

Kana iwe uchida kugadzira chigadzirwa kana purojekiti, midziyo yehardware inotakura isingadzivisike, uye mabhokisi epurasitiki ari kufarirwa zvakanyanya.Kugadzirwa kwematehwe epurasitiki kunofanirwa kuve kusingaparadzaniswe kubva kune jekiseni mold.SeChinese jekiseni rekugadzira mold uye mutengesi, isu tine anopfuura makore gumi eruzivo rwekunze uye tinoziva nezvinodiwa mold yevatengi munyika dzakasiyana.Nhasi tichataura nezve izvo zvikamu zvekuumbwa zveUS SP1-SPE standard, uye ndinovimba zvichabatsira kwauri.

1. Class 101 molds (SP1-SPE chiyero 1,000,000 doro kana kupfuura, kwenguva refu-yenguva chaiyo kugadzira molds)

1).Detailed mold structure inodhirowa inodiwa;

2).Iko kuomarara kweiyo mold isina chinhu ndeye 28HB (DME #2 simbi/king material electroplating nickel/P20 electroplating Nickel);

3).Simbi yemodule yemukati ine glue inofanira kuomeswa kusvika ku48 ~ 52HRC, uye zvimwe zvikamu zvakadai sezvinzvimbo zvemutsara, makiyi ekudhinda, beading, nezvimwewo zvinofanirawo kuva hardware;

4).Iyo ejector ndiro inofanirwa kunge iine magidhi posts;

5).Mitsara

6).Kana zvichidikanwa, iyo yepamusoro mold, yakaderera mold uye mutsara chinzvimbo chinofanira kuve nekudzora tembiricha;

7).Pamatanho ese emvura, zvinokurudzirwa kushandisa electroless nickel dipping kana 420 simbi isina tsvina setemplate, iyo inogona kudzivirira ngura uye kuchenesa marara;

8).Kukiya kukiya kana oblique lock kunodiwa.

2. Type 102 molds (hapana kudarika 1,000,000 doro, kugadzirwa kwakawanda kwezviumbwa)

1).Detailed mold structure diagram inodiwa;

2).Iyo shoma kuomarara kweiyo mold base material ndeye 165BHN (DME #2 simbi/AISI1050);

3).Mukati mamodules ane glue zvinzvimbo Simbi inofanira kuomeswa kusvika zvishoma 48 ~ 52HRC, uye zvimwe zvikamu zvinobatsira zvinofanira kubatwa nenzira imwechete;

4).Inokurudzirwa kushandisa zvivharo zvakananga kana oblique lock;

5).Zvinhu zvinotevera zvinogona kana kusadiwa, zvichienderana nehuwandu hwekupedzisira hwekugadzira.Zvinokurudzirwa kutaura Paunenge uchishandisa zvinhu zvinotevera, tarisa kana zvichidiwa: A. Ejector plate guide post, B. Row position hard sheet, C. Electroplating water delivery gole, D. Electroplating mold cavity.

3. Nyora 103 molds (pasi pe500,000 doro, yepakati-vhoriyamu kugadzira mold)

1).Iyo yakadzama mold chimiro dhizaini inodiwa;

2).Iko kuomarara kweiyo mold base material ndeye 165BHN (DME #1 simbi/1040 simbi/S50C);

3).Iyo simbi yezvinhu zvemukati mold ndeye P20 (28 ~ 32HRC) kana yakakwirira kuoma (36 ~ 38HRC);

4).Zvimwe zvese zvinodiwa zvinoenderana nezvinodiwa.

4. Type 104 molds (isingasviki 100,000 doro, madiki ekugadzira mold)

1).Detailed mold structure diagram inodiwa;

2).Simbi yakapfava kana aruminiyamu (1040 simbi) inogona kushandiswa kuumba hwaro zvinhu P20 (28~32HRC);

3).Zviumbwa zvemukati zvinogona kushandiswa Aluminium, simbi yakapfava kana mamwe masimbi anotenderwa;

4).Zvimwe zvinodiwa zvinoenderana nezvinodiwa.

5. Nyora zviumbwa zana neshanu (zvisingasviki mazana mashanu edoro, yekutanga mold kana test mold)

Aluminium casting kana epoxy resin kana chero chinhu chinogona kushandiswa chero iine simba rakakwana kuburitsa huwandu hushoma hwebvunzo.

Nguva yekutumira: Jul-10-2023